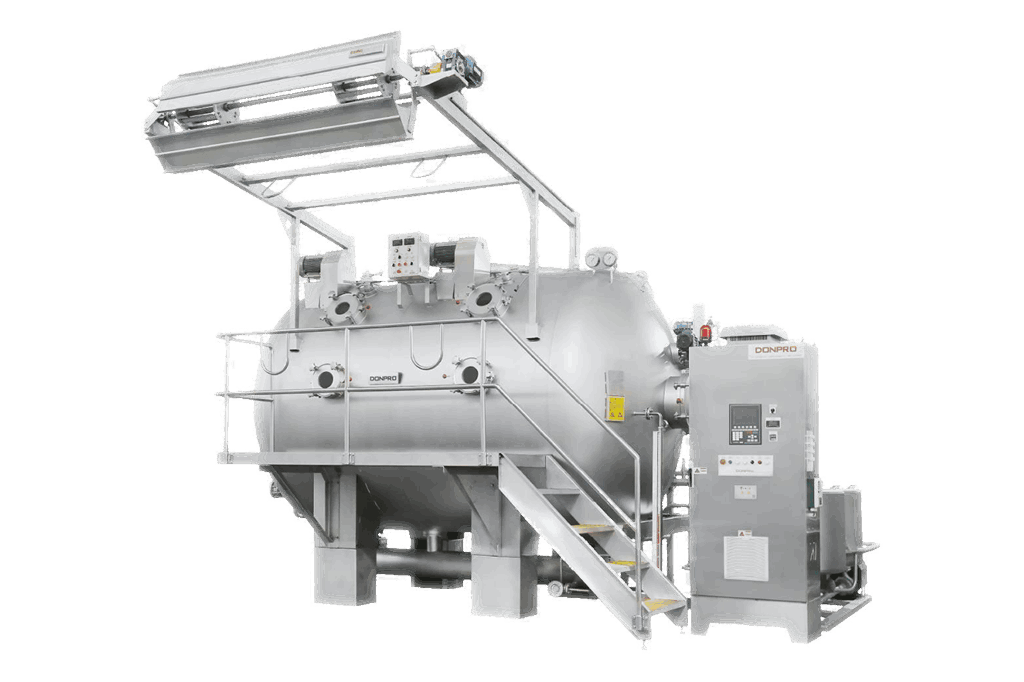

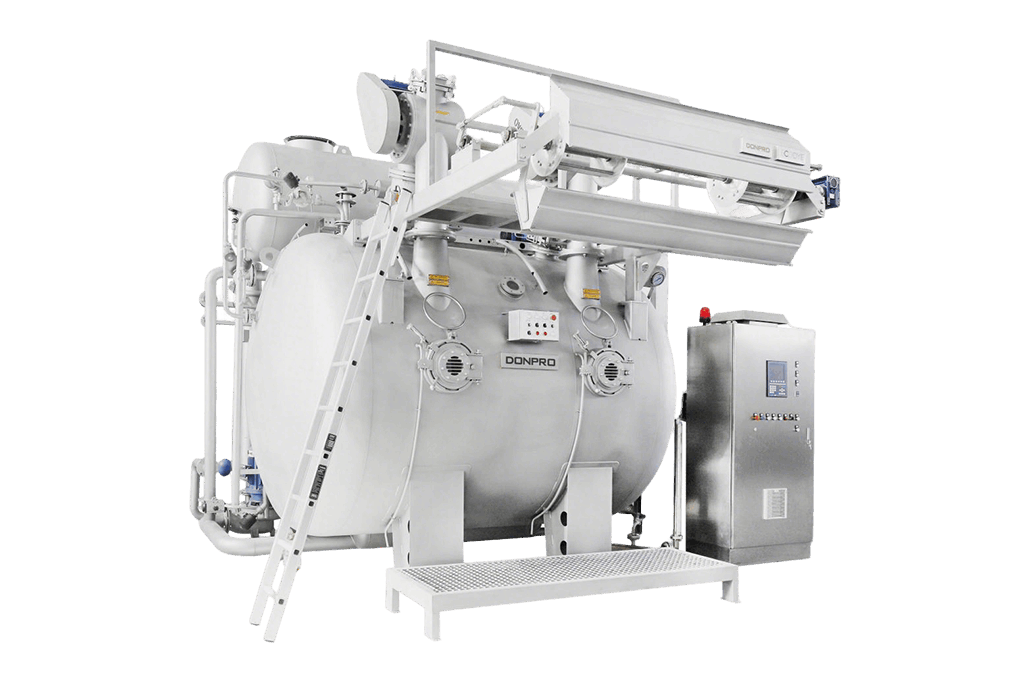

Main tank & liquor carrying parts are made of Stainless steel 316L

Automatic touch screen controller

Working temperature:140℃

Inverter controlled main pump motor

Proportional heating and cooling

Powder coating Stainless steel control cabinet

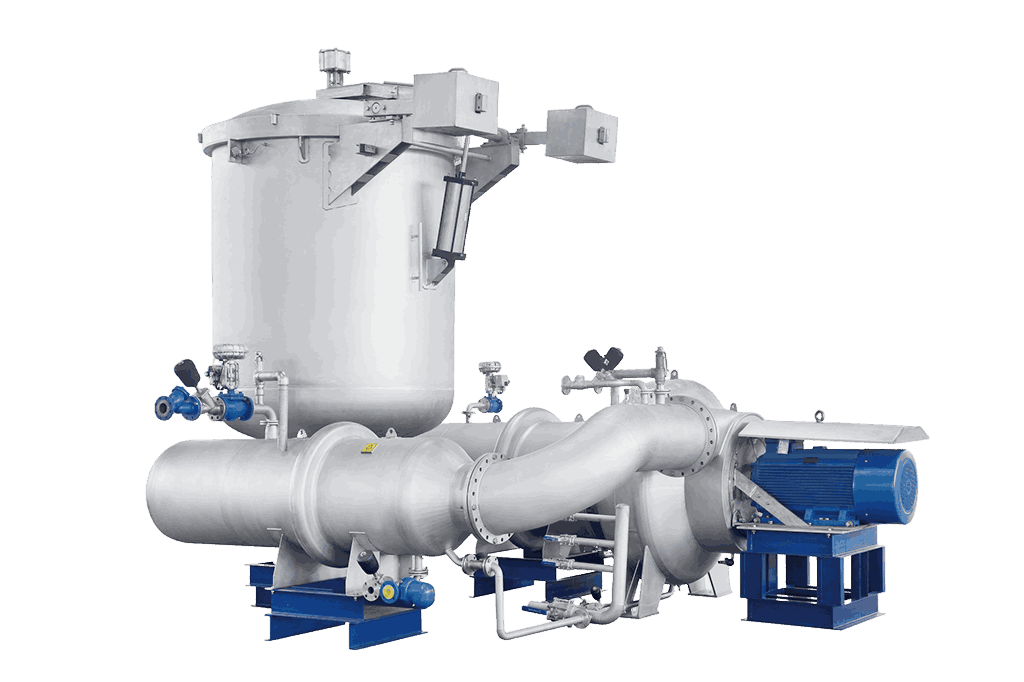

PED ECODYE

Suitable for package yarn.The fiber includes cotton,polyester cotton,acrylic,wool,polyester,artificial fiber, blended, etc.

Main features

STANDARD EQUIPMENT

SPECIFICATIONS

Note: Specifications of the above machines are only for reference. The company reserves the right of alteration.