STANDARD

| OPTIONAL

|

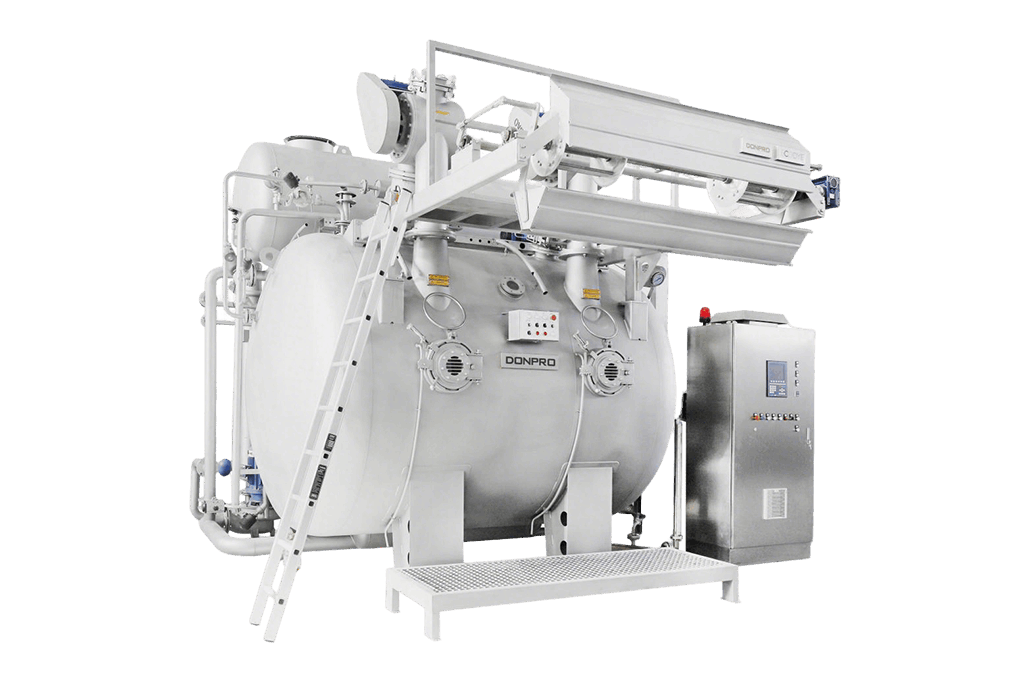

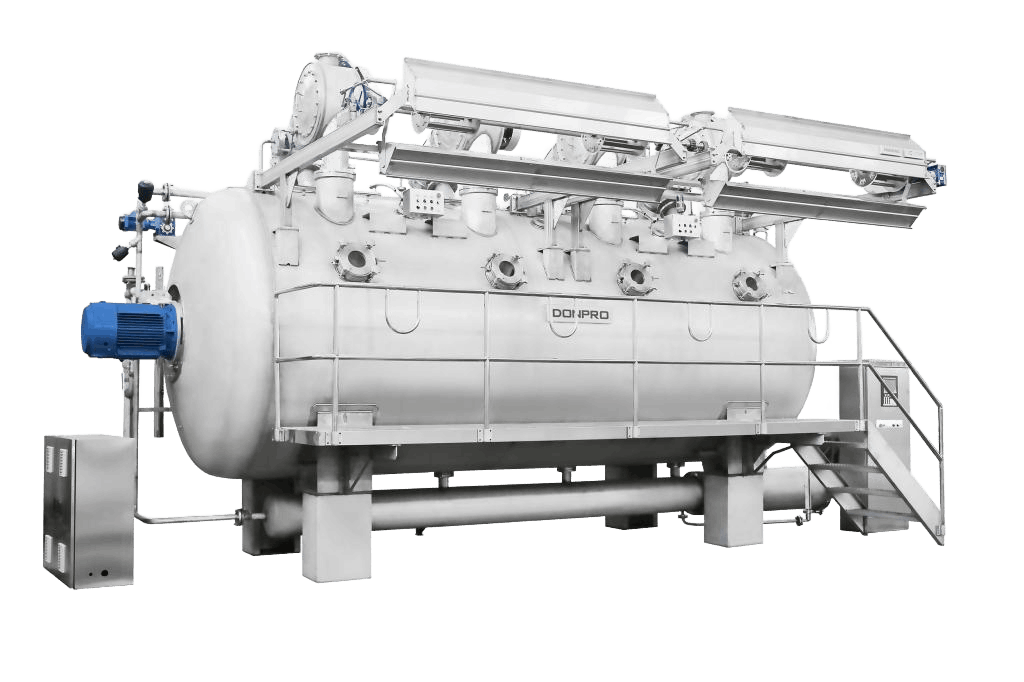

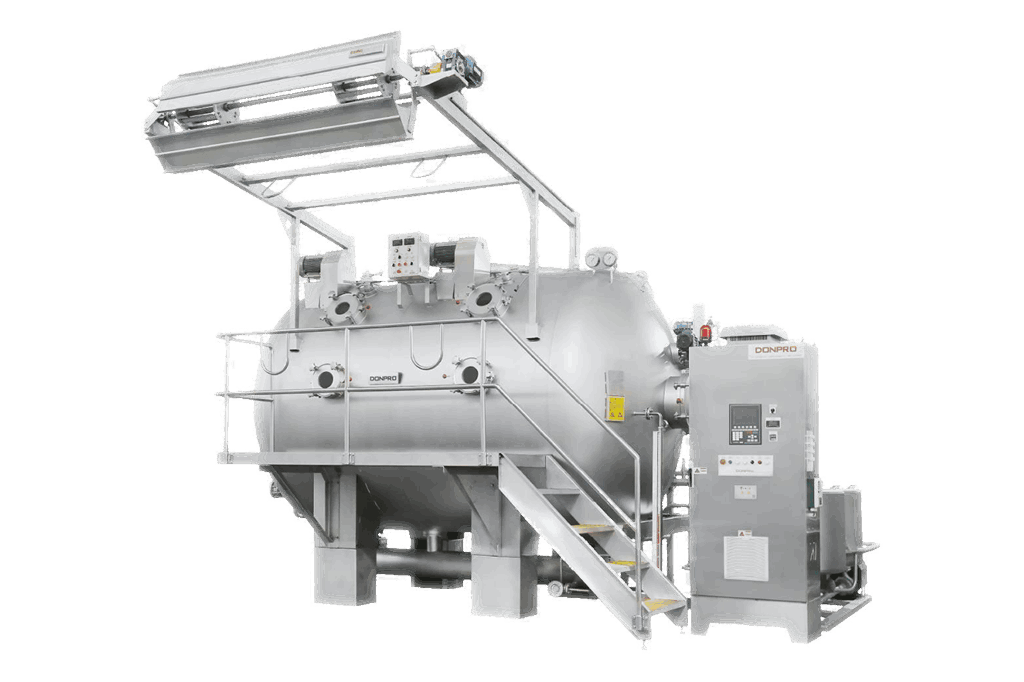

SOFT FLOW PRO ECODYE

Suitable for 100% knit cotton, chemical fiber fabrics, woven fabric, etc.

TECHNICAL FEATURES

TECHNICAL FEATURES

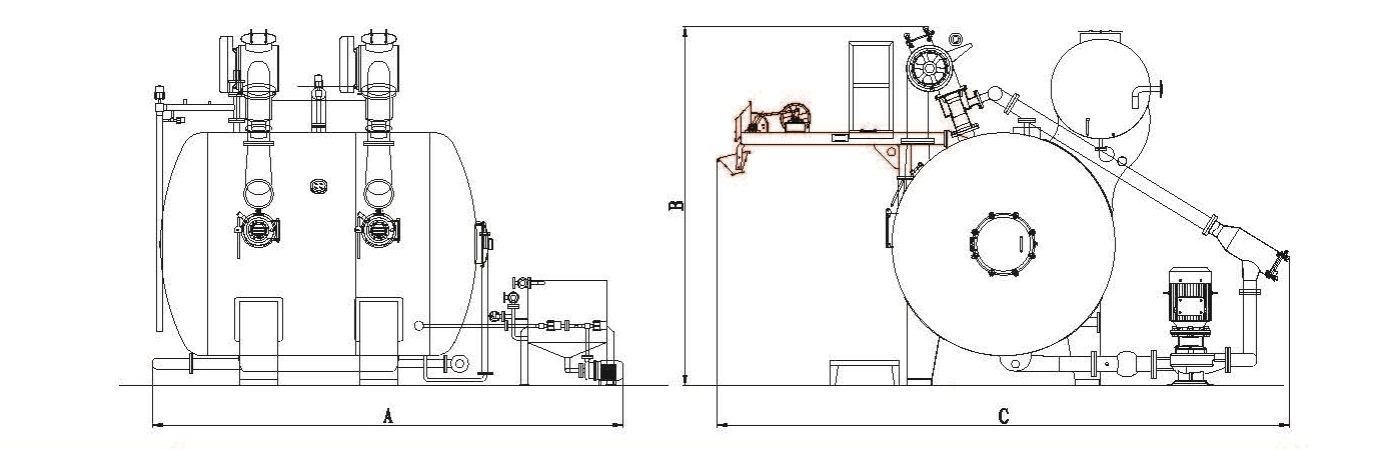

SPECIFICATIONS

Note: Specifications of the above machines are only for reference. The company reserves the right of alteration.