STANDARD

| OPTIONAL

|

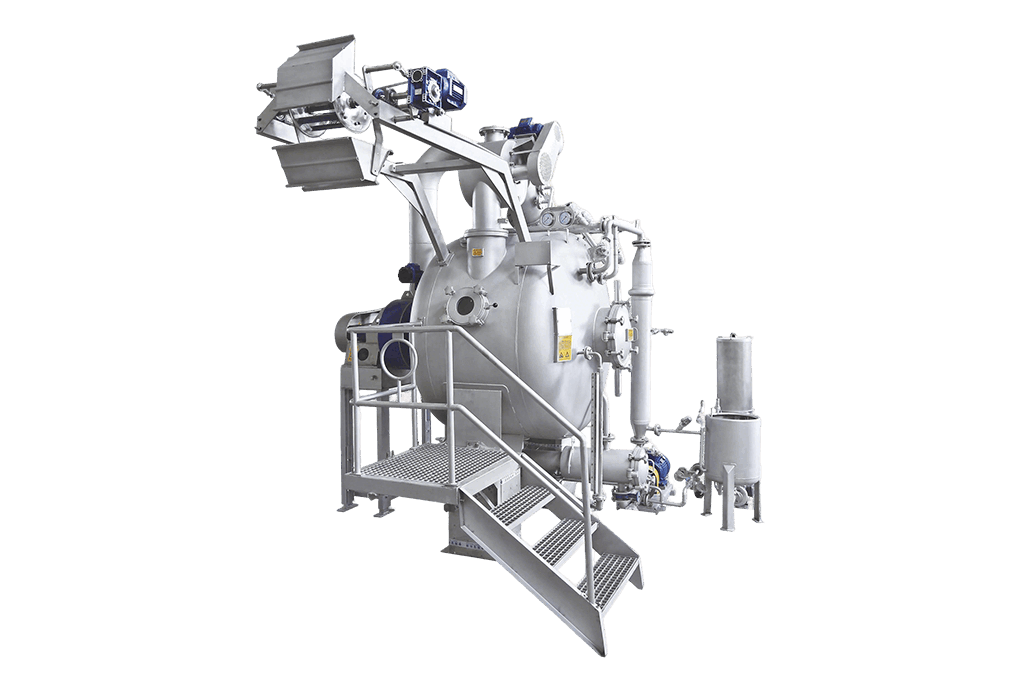

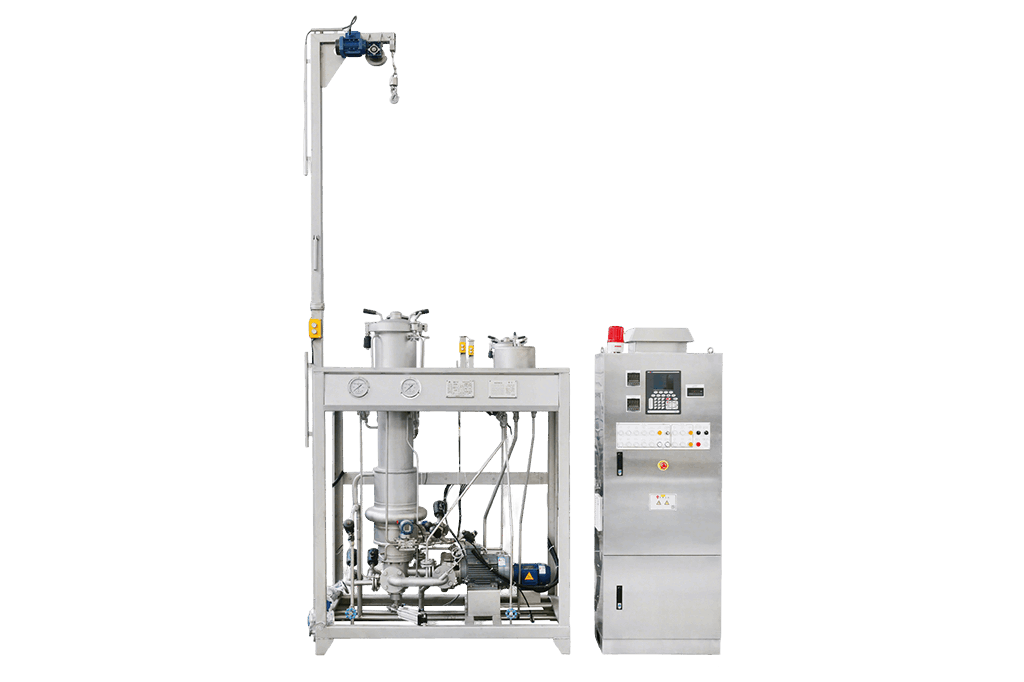

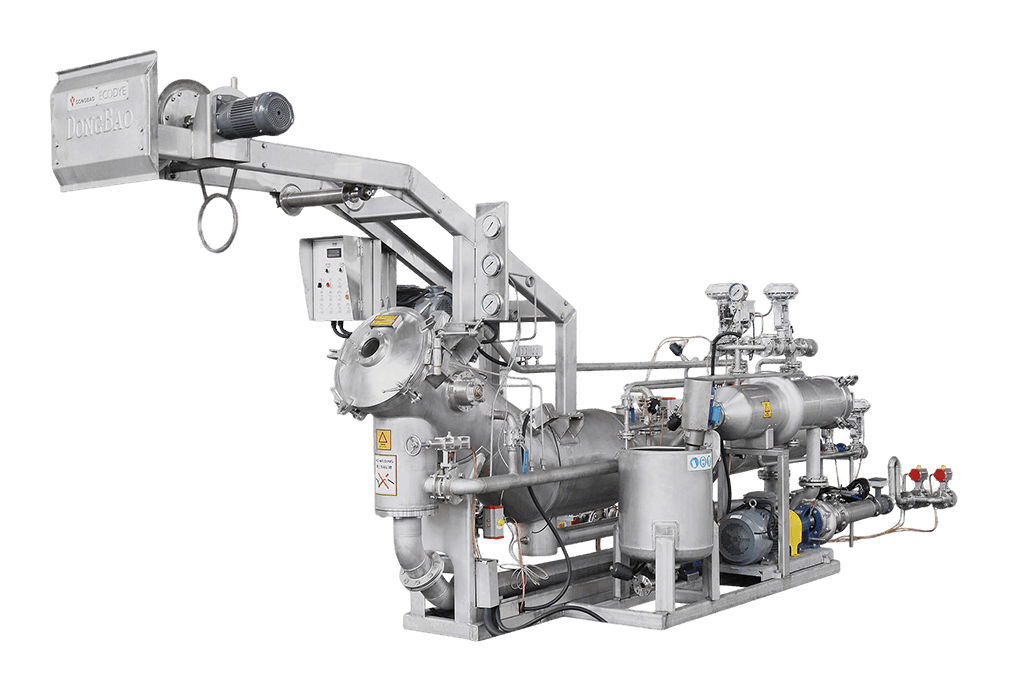

HTHP Multi Flow Sample Dyeing Machine

The route to efficient fabric dyeing starts in the laboratory and with small scale production.Suitable for Nylon lace, woven TC , TR, cotton plain weave, cotton pique, polyester chiffon, satin chiffon, CEY, etc.