STANDARD

| OPTIONAL

|

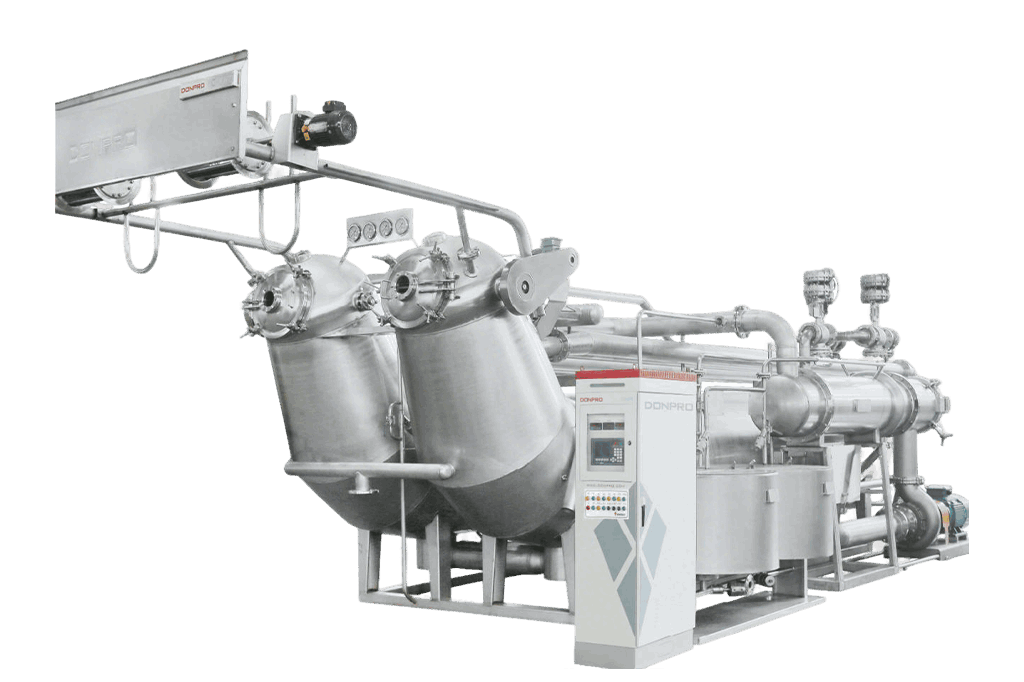

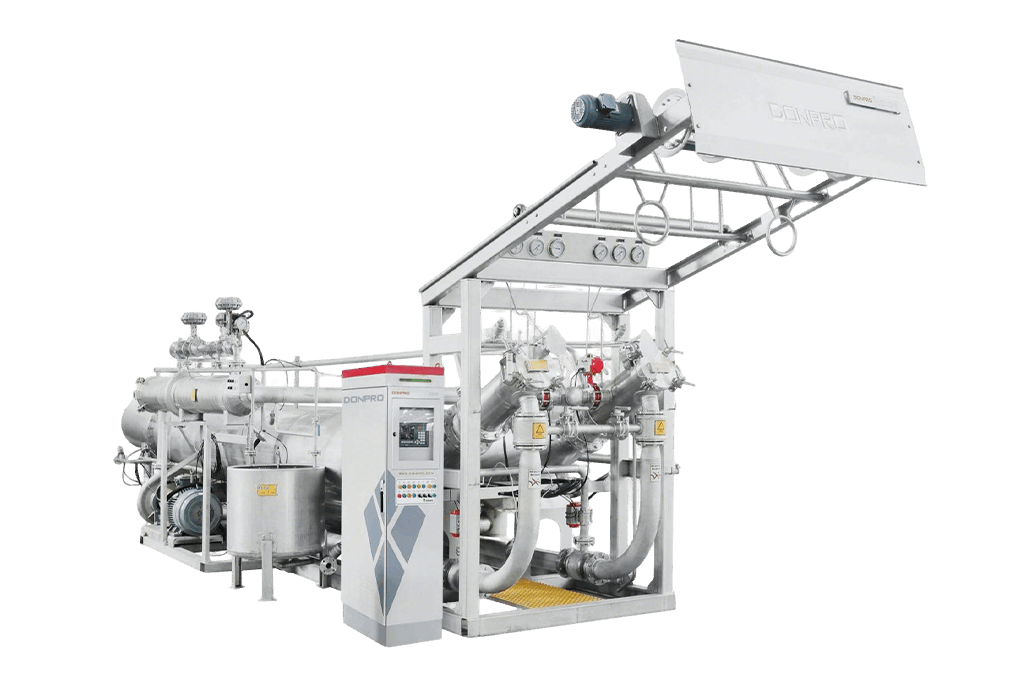

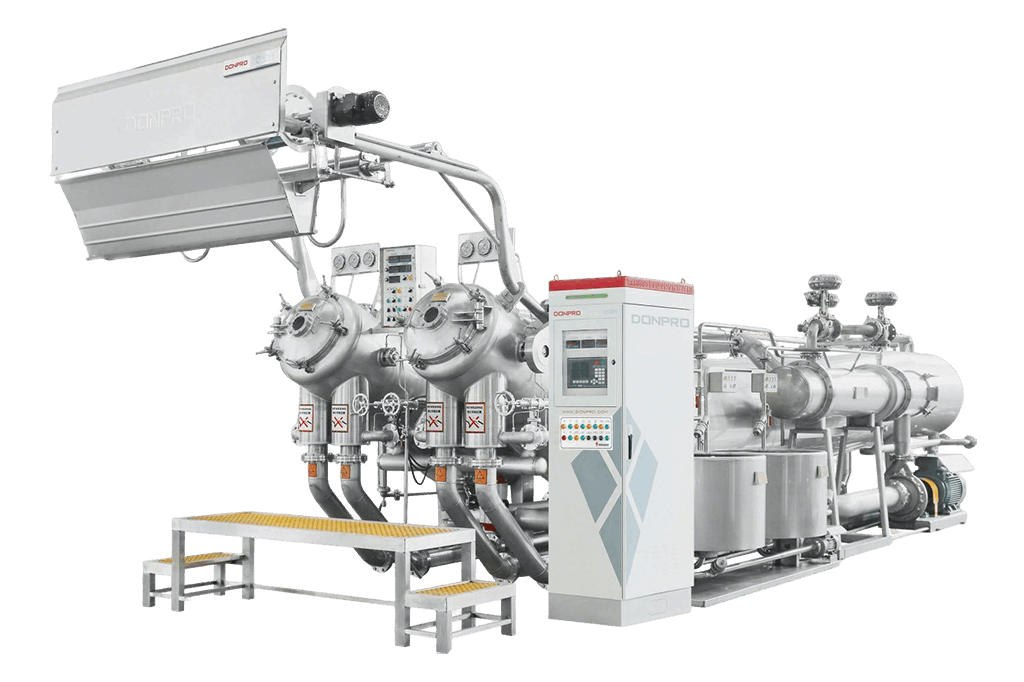

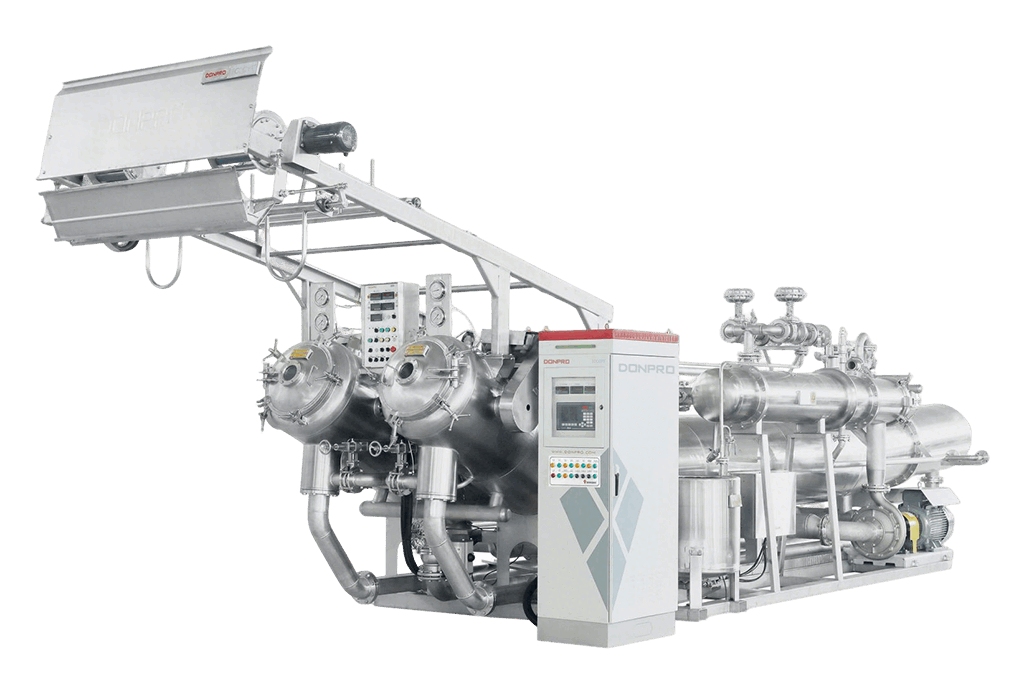

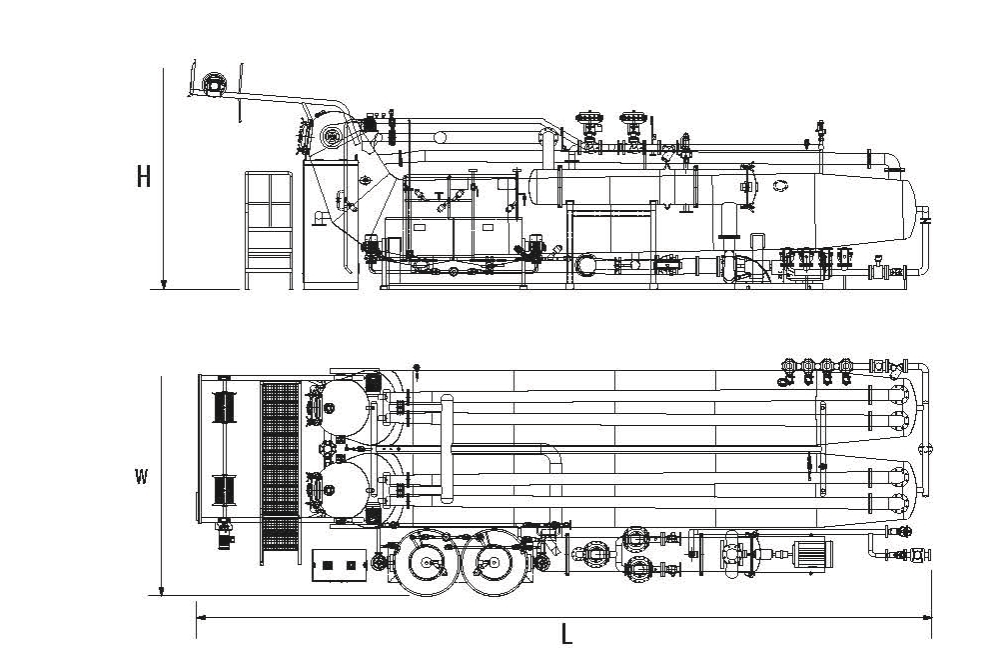

JED Jumbo ECODYE

Suitable for woven or knitted fabrics: N100%, T100%, T/C, N+OP, T+OP, CVC, T/R, N/C and N/T. Also micro fiber fabrics like TRICOT, poly-peach skin, micro suede and jacquard, etc.

TECHNICAL FEATURES

CONFIGURATIONS

SPECIFICATIONS

Note: Specifications of the above machines are only for reference. The company reserves the right of alteration.